Production

We produce aluminum sheets, insoles for steel kitchenware and aluminum discs for Teflon-coated kitchenware in an indoor area of 10.000 m² in Kahramanmaraş Organized Industrial Zone to meet the domestic market demand.

Casting:

Slab casting and cast roll production is produced in our casting facility no. 1 and 2 with melting and holding furnaces.

In our facility, sheets and discs are produced from 1000 series alloys (1050-1100-1200) in the requested conditions, size, and surface qualities.

Technology-oriented production is carried out with special raw material loading vehicles, liquid metal refining, and filtering systems in the casting lines.

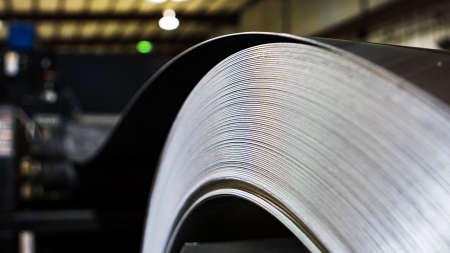

Rolling mill:

Sheets, coils and horizontal casted slabs coming from the casting are reduced to semi-finish thicknesses with reversible cold rolling mills and are delivered to the final thickness in the finishing mills. Material production can be realized with low thickness tolerances.

Heat Treatment:

Aluminum sheets and discs coming out of the cold finishing mills are made ready for shipment by being subjected to heat treatment according to the area of use, the process to be processed or in the conditions requested.

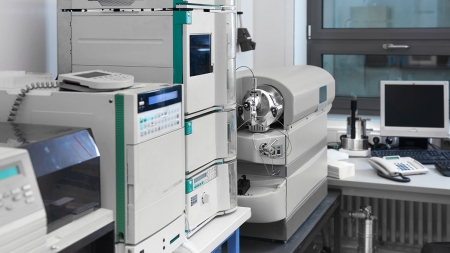

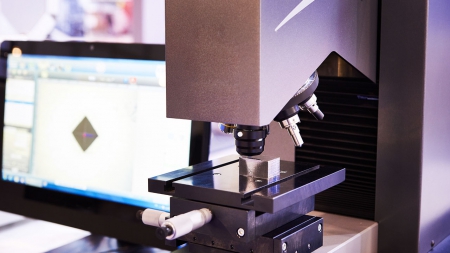

Quality Control:

In the quality control laboratory; standardization was achieved in production by controlling and testing micro and macro etching, tensile test, chemical analysis measurements with Oes, HB hardness test.

Casting:

Slab casting and cast roll production is produced in our casting facility no. 1 and 2 with melting and holding furnaces.

In our facility, sheets and discs are produced from 1000 series alloys (1050-1100-1200) in the requested conditions, size, and surface qualities.

Technology-oriented production is carried out with special raw material loading vehicles, liquid metal refining, and filtering systems in the casting lines.

Rolling mill:

Sheets, coils and horizontal casted slabs coming from the casting are reduced to semi-finish thicknesses with reversible cold rolling mills and are delivered to the final thickness in the finishing mills. Material production can be realized with low thickness tolerances.

Heat Treatment:

Aluminum sheets and discs coming out of the cold finishing mills are made ready for shipment by being subjected to heat treatment according to the area of use, the process to be processed or in the conditions requested.

Quality Control:

In the quality control laboratory; standardization was achieved in production by controlling and testing micro and macro etching, tensile test, chemical analysis measurements with Oes, HB hardness test.